No, that is incorrect.. Many decisions has been made!

It is incredible, I have procrastinated the heck out of this post, at first because I didn’t really have any news and then because it had passed so much time I didn’t know where to start and what to write about. But I will make an effort to start updating more regularly, not just so that you get to follow me more closely, but also so that I can do shorter, easier posts each time.

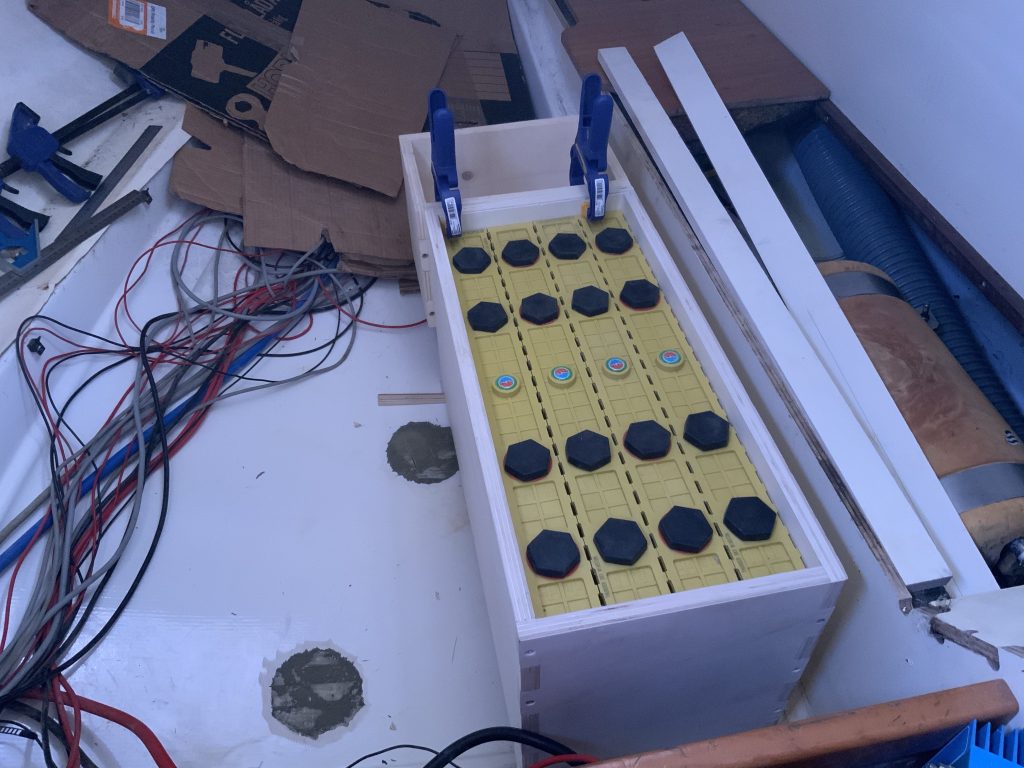

So, what have I’ve been up to? Well, as you all know by now, I’m working on my battery upgrade. A few weeks ago I managed to get my hands on some high quality plywood, albeit 18 mm thick, and since then I have been building myself a box for the batteries. It shouldn’t take more than a couple of days, one might think, but on a boat everything takes so much longer, especially as I had to get some more tools. But the box is done. Totally over-built with finger joints and all. I also figured out that I have to raise the bed 36 mm (or more exactly, the height of two layers of the plywood which I will add as a rim to the bed) to get the battery box to fit. It was known I had to do this from the beginning, even if I wanted to have the cells stacked on the side rather than standing upright. According to the manufacturer that is not an accepted installation position though. So I had to make other plans.

What else have I done? Well, I gave the boat a good reorganization, as it was getting more and more cluttered with things that didn’t have a home. The table was full of things, the floor in the salon also. One of the quarterbirths (a fancy name for one of the staterooms (an even fancier name for a room on a boat) in the stern, or aft, of a boat)) was filled with cardboard boxes and other junk that I just needed to throw out. I just can’t understand why I kept filling it with things that actually should get thrown away instead. Well, I kind of understand, because “you never know when it can be useful”. That, combined with a constantly low energy level, in many ways due to the state of the boat actually, all added up. Eventually it was just too much to handle, just the thought of cleaning it out made me procrastinate.

But one day I found some energy, cleaned it out and of course, when I was done, I thought “why haven’t I done this earlier?!”. Well, we all know how it is when low on energy. In your mind every hill is a mountain, every kilo a ton. This time I won, I got it all sorted and could move on. As the quarterbirth was cleared, I immediately filled it with new stuff – useful stuff, stuff that mostly will be installed in the other quarterbirth or in the technical department behind the quarterbirths. So when the lithium batteries are installed, all of that will be in their right places.

Talking about batteries, I am in the final stages of actually putting my battery box into place. When I removed the old battery box it was not attached to the boat, at all. So it was easy to lift out. It also moved when I literally hit rock bottom as I arrived to Spain, so having a solid bond to the boat is important. They had tried to attach the old battery box to the boat as seen in the above picture, using large globs of polyester resin, but it doesn’t adhere well to oily plastics as we all know. In the center of each glob there was some remains of steel bolts, but they were all rusted out so they didn’t help much. Who puts bolts that isn’t stainless in a permanent fixture on a sailboat..? That’s just crazy… and cheap. And shortsighted. And expected on a former charter boat, I guess.

Anyway, removing those polyester blobs I was a little too eager, apparently. They are hard as rock and I only saw two possible ways to get them off, either grind them down entirely by using the grinder and spreading dust everywhere, requiring a full clean of the boat, or slicing them up with the grinder and then using a hammer to break them off in the hope that there would be less to grind off in the end.

I went for the latter.

By doing that I gained some knowledge. First of all, a grinder with a cutting blade does cut though polyester resin like butter, so be aware when the polyester ends and where the gelcoat begins. I didn’t prefect this, so some cuts got a little deep. But not through-the-hull-deep though, I’m not that stupid. I think. The second thing I learned is that polyester resin really grabs on to gel coat. More than gel coat grabs on to epoxy resin and the underlying fiberglass. So when knocking the pieces off I realized that I instantly got down to bare fiberglass, yay… Well, As I needed to fix the first piece I removed, I could just go ahead and knock the rest of the polyester resin blobs clean from the hull as well. I mean, I have to buy gel coat anyway and get all the needed tools (it later showed I had all the tools needed) and do the job, so why not, it was a fast and simple way to get the polyester glob off the hull and I was concerned that if I stop now I would lose the energy and postpone the job for a later day. So, job done.

I sanded the gelcoat and the fiberglass to a reasonably smooth finish, feathering out the gelcoat so that it would look good enough and be ready for fairing. I had some finishing fairing compound left since I faired the keel, so I mixed up a batch and proceeded to apply it. There were some complex shapes as the polyester globs had pulled a little of the edges of the grid tabbing off (the grid is what gives the hull rigidity) and I tried to restore it by applying the fairing a little excessive. It worked nicely, the day after I could sand most of it down again and restore the edge form. The repair will mostly be covered by the battery box anyway, but I figure it could be a good thing to practice a little for when it really counts.

I went to the marine store in the boat yard and got some gelcoat, the language barrier was obvious as I don’t know how to talk boat in Spanish, heck, I can’t hardly talk boat in English! But I made my self understood, as I said that I needed white gelcoat (like, “yo quiero comprar blanco gelcoat, por favor”), and he answered “blanco, blanco gelcoat?” and I was “sí, un poco” and he was “una kilo” and I was like “okay…” I got a can and a bottle of catalyst in the end and went to the boat for some exploratory mixing. And, yeah, it failed. It never kicked off and only turned into chewing gum. So I had to scrape it off and clean it all with acetone and try again. This time a little more scientific. I needed to have 1.5% – 2.5% of catalyst by weight so I measured up 100 grams on my not-so-precise household scale and added about 2 grams of catalyst. It seems to have worked much better. I rolled it onto the patches and have now let it harden for a good 24 hours. They seem to be hard enough so that I can sand them a bit and apply the next layer. Hopefully it will not require more than that, but I will do a third layer if needs be, it is mostly just to make it look nicer. When this is done, it is time to mix up some thickened epoxy and glue the battery box to the boat, exciting times! More on this later.

Another thing that has been adding to my anxiety lately has been my dinghy, or tender. I have an inflatable tender, or as I call it a deflatable tender, as it autodeflates at an alarming rate, and the floor of the tender now has two fairly large holes in awkward positions so that it is hard to repair it. So… I ordered a new tender! Yay! It is surprisingly hard to come to a decision when it comes to what to get and how much money I’m prepared to spend on a tender. A tender, for you who isn’t avid boaters, is what a car is to a home. It is the one thing that connects you to shore when you live onboard and mainly anchor your boat out of marinas. So it is a rather important piece of the puzzle to get a working and satisfying life onboard.

Therefore I believe it is something where it is worth to put a little extra money, really. So today I accepted the quote I got from Offshore Cruising Tender in New Zeeland for a OC300!

(No it is not me in the picture, I haven’t got any OC tender yet!) Unfortunately I have been postponing this decision for so long that I will not get the tender in May and as I’m leaving the marina at the end of April it means that I either have to come back to the marina to collect it if I decide to ship it here, or, which I believe is how I will do it, to Gibraltar. The main reason to send it to Gibraltar is taxes, really. But I will contact a shipping company in Gibraltar and talk to them to find out what costs that are associated with importing a tender from New Zeeland.

Anyway, I’m happy to have made the decision, all I have to do now is to find a matching outboard as the one I have is a bit weak. I need one that have a good reputation, good service network around the world and is easy to work with in case of any issues. I’m leaning towards a 10-15hp Honda or Yamaha at the moment, but if you have any suggestions I’m all ears!

I usually don’t comment the Covid-19 situation, but as we’re in a lock down here in Spain it does complicate things further, and as all pubs and restaurants have to close at 6pm and it is a curfew at 10pm social life does take a hit and in the same time as we are confined mainly to the municipality it is hard to source materials. It wasn’t easy before either, but this doesn’t help either. Normally we have been spared any cases here in Almerimar and especially in the marina, but during these weeks we have had one case on one of the boats which of course actualizes the situation even more. In general boaters are fairly isolated and when we meet it is usually in open air, so the concern of catching the pandemic is generally low among us. But as we hunker down for winter we tend to cluster in marinas and thus it is harder to keep apart. I hope that this is over soon, even if it seems that it will get worse before it gets better. To add to this it rained today and is forecasted to rain to morrow as well. Oh, the misery.

Enough of this, time to gear up and do some sanding before applying more gelcoat! I’ll get back with a new report soon, I promise!